Product Introduction:

Fully Auto Mechanical structure, 1.) Automatic equipment of defending leaning:Never cut obliquely and no need to adjust.2.) Stainless steel cylinder table-board:mud strips reaches the right place automatically; accurate positioning to avoid wasting the mud; saving oil 70%-100% than the normal table-board.

3.) Stainless steel push board: wear resistant, the working life is longer 3 times than the normal one.

4.) Oriented angle and Oriented arc: high accuracy to make the steel wires go into groove, reduce 90% broken steel wires averagely.

5.) High-abrasive material craft: Leader is hard chrome plate and the compound oriented bearing. Its resistance is small and its working life is long.The cutting steel wire of the slitter is pneumatically tightened, and the tension of the steel wire can be adjusted according to different products, which not only achieves the effect of sharp steel wire cutting and neat section, but also improves the service life of the steel wire.

Advantages:

1.) Buffer power accumulator: absorb return impact, and translate it to push power.

2.) High strength, large thrust: mainly usages for the mud strip whose original material is coal gangue and shale.It’s suitable for different soft and hard plasticity mud strips: it’s saving oil When usages for high sand content mud or other inferior mud; if the mud strips is very soft, the expansion table-board should be intense in advance.

delivering a high (8%-30%) moisture content of raw materials,the most widely used clay cutter machine.

Product Parts:

Alloy mixer blades |

Alloy hollow brick mould |

Alloy brick mould |

Auger |

Thrust bearing |

Reducer |

| Auger adopts high chromium raw materials,the auger front part can produce 25million bricks,the auger back part can produce 45 million bricks one time. | High load capacity to admit any pressure from soft to stiff extrusion condition. | Reducers with parallel shafts,case hardened and ground helical gears to ensure secure,progressive transmission and quiet operation and long durability. |

Extruder shaft |

Liner |

| Extruder shaft and gear adopts heat treatment.If with proper maintenance,we can give at least 4 years guarantee for gears and shaft. | 1.Hinged body.Easy opening for maintenance tasks and part replacement.

2.Highly wear resistant chrome alloy liners with a bolt-free system,preventing air leaks and making replacement operations easier. |

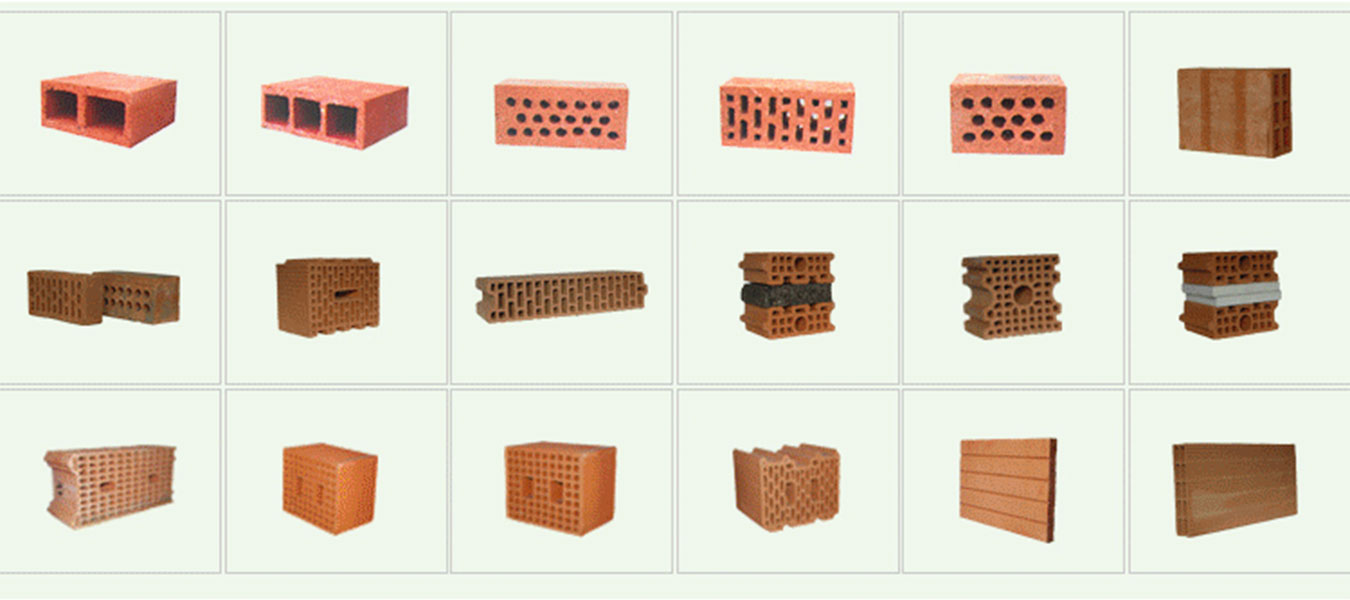

Making different bricks: