Product Introduction:

The Simple Auto stacking system is the key equipment for the production of high-grade wall materials automation, and it is also the equipment which is widely used in the production of high-grade wall materials in developed countries. This system adheres to the design idea of COSMEC Italy, which owns advanced technology, high degree of automation level and high stability. The system consists of green brick cutting, grouping and loading on pallet, pallet transfer, pallet temporary storage, pallet loading and unloading, dry brick unloading from pallet, grouping, spacing and setting etc. This entire system is controlled by high-end PLC, which links each intelligent unit through PROFIBUS, and achieves the automatic operation of data setting or adjustment through industrial computer. This system is suitable for the production of both various common wall materials and high-grade wall materials.

MAIN FEATURES:

1.Fast speed,high efficiency,big capacity,

The maximum capacity exceeds 30,000 pcs/hr;

2.Low electric consumption,low cost;

3.Driving by servo motor,running smoothly,high automatic;

4.Simple craft,reliable machine;

5.Flexible,save room and strong site adaptability;

6.Suitable for all kinds of bricks.

APPLICATIONS:

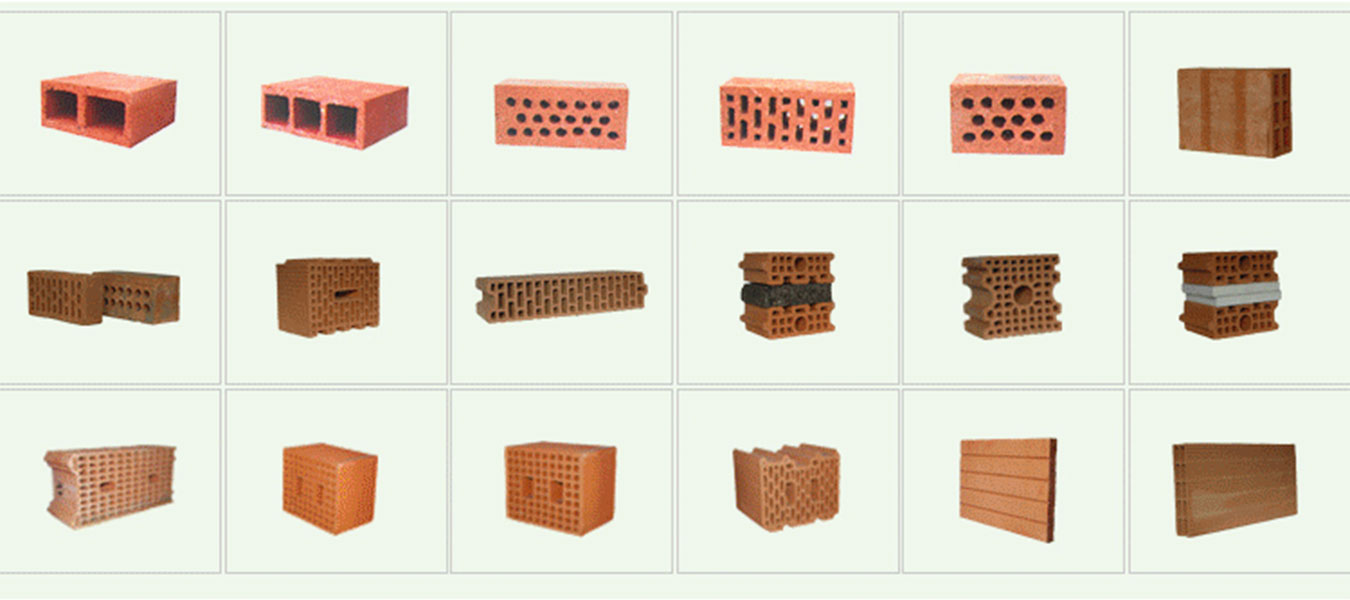

simple structure,standard brick, Multi-hole brick, building blocks,etc.

MORE SAFETY:

The intelligent gripper realizes soft contact with the surface of green bricks to ensure good shape of green bricks.Three dimensional rotated spatial positioning realizes the overlapping of each layer to ensure the height of piles and stability.

TECHNICAL PARAMETERES:

Working environment:the width of tunnel kiln is from 2.5 m~4.2 m

Work cycle:40~60s for each work cycle

Higher:standard layers is 13(can be adjusted according to the height of kiln),much higher than artifical stacking

Faster:stacking 280 pieces to 460 pieces for standard bricks in one time( can be adjusted according to the height of kiln),realize high speed catching,moving and stacking by adjusting variable frequency inverter.

Advantages:

This stacking system carries Janpan’s FANUC and siemens electronic integrated system that has various smart functions.

Product Parts:

Alloy mixer blades |

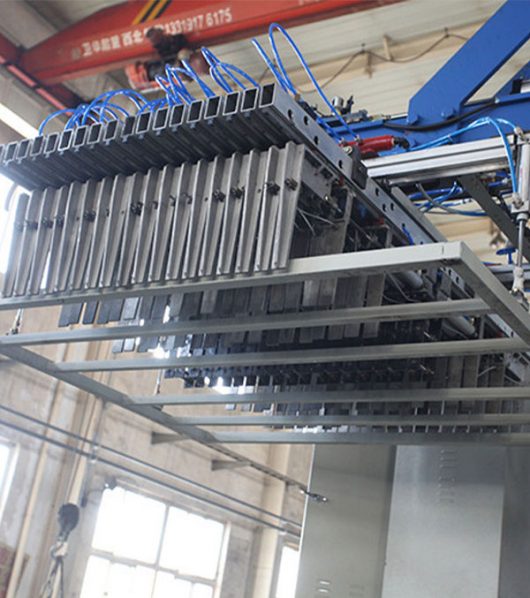

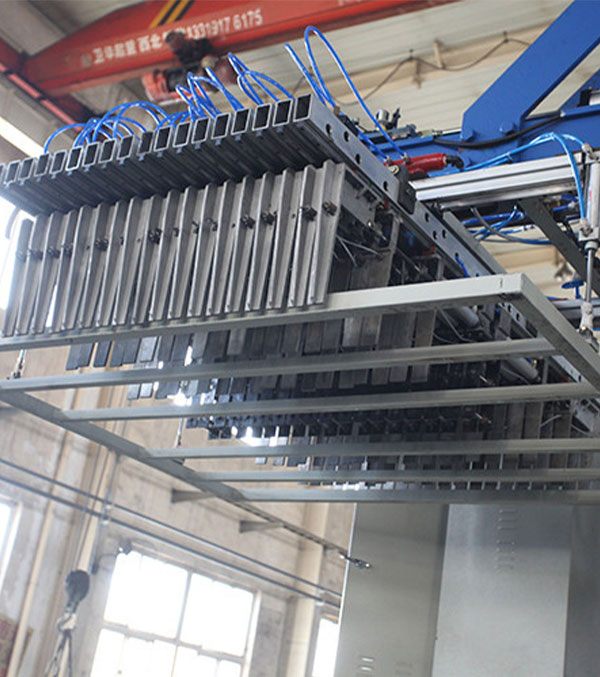

Alloy hollow brick mould |

Alloy brick mould |

Auger |

Thrust bearing |

Reducer |

| Auger adopts high chromium raw materials,the auger front part can produce 25million bricks,the auger back part can produce 45 million bricks one time. | High load capacity to admit any pressure from soft to stiff extrusion condition. | Reducers with parallel shafts,case hardened and ground helical gears to ensure secure,progressive transmission and quiet operation and long durability. |

Extruder shaft |

Liner |

| Extruder shaft and gear adopts heat treatment.If with proper maintenance,we can give at least 4 years guarantee for gears and shaft. | 1.Hinged body.Easy opening for maintenance tasks and part replacement.

2.Highly wear resistant chrome alloy liners with a bolt-free system,preventing air leaks and making replacement operations easier. |

Making different bricks: