レンガの強さ

The strength of sintered bricks is of concern to major construction units, and there are many technical measures to improve the strength of sintered bricks. Below are a few brief introductions:

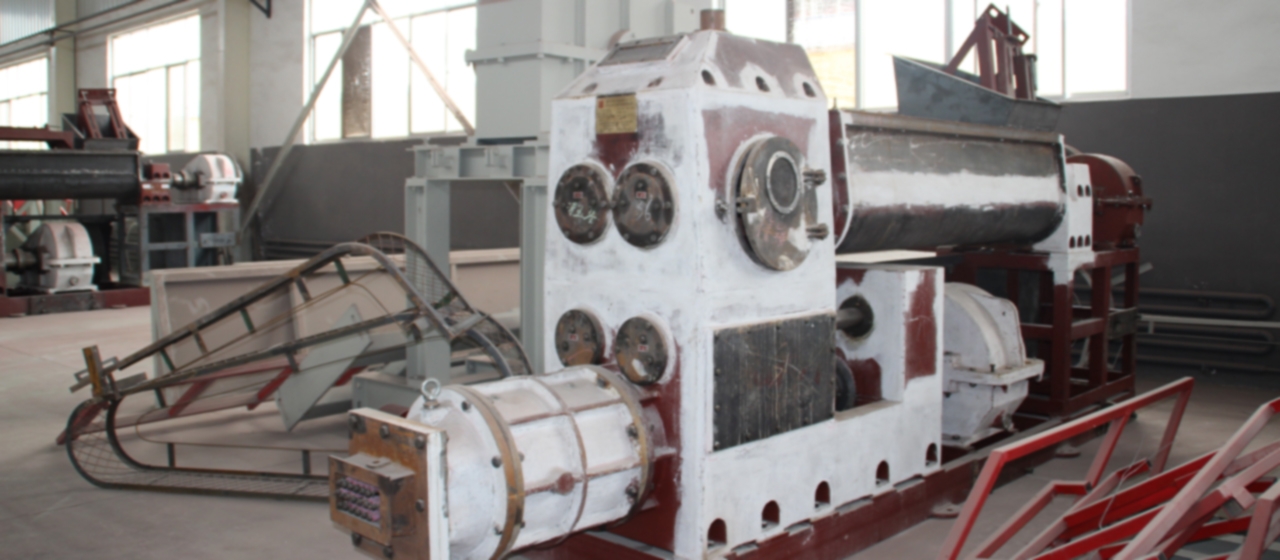

1. Increase the molding pressure of the brick machine

The increase in molding pressure of the brick machine leads to an increase in the density of the bricks. Only by increasing the density of the adobe. Only by increasing the density of the adobe can high-strength sintered bricks be fired. Practice has shown that bricks with a molding pressure of (2.2-2.3) MPa generally have a compressive strength of (13.9-15) MPa when fired, while bricks with a molding pressure of 3 MPa can easily reach a compressive strength of 20 MPa when fired.

2. Appropriately increasing the temperature of sintered bricks

The strength of bricks produced by the same raw materials and brick machines varies depending on the roasting temperature. 試験結果は、レンガの圧縮強度がトンネルキルン焙焼温度の上昇とともに増加することを示しています.

3. 保温時間を適切に延長する

同じ焼結レンガ原料, 同じレンガマシン, 同じ加熱速度と冷却速度, 焼結温度はすべて 900 ℃, 保温時間が違います, したがって、焼結レンガの圧縮強度も異なります. 適切な断熱時間は、焼結レンガの圧縮強度と品質の向上に役立ちます。.

4. Recommend using low-temperature long burning

最近では, sintered bricks are commonly mixed with internal combustion, と “high-temperature short firing” is often used to increase production. Practice has proven that using the “high-temperature short burning” firing method for internal combustion conversion can increase production, but it has a certain impact on product quality. Products often have defects such as black centers, black scars, cracks, and embossing, and their compressive strength is also reduced. さらに重要なことには, it increases coal consumption, wastes energy, and is detrimental to protecting the ecological environment. したがって, it is recommended to adopt the method of “low-temperature and long-term burning”. Using the low-temperature long burning method, under the condition of internal combustion of about 80%, the temperature range from (650 に 900) ℃ should not be less than 6 時間; The interval from 900 ℃ to the end of product sintering should not be less than 6 時間. この上, it takes a total of 12 hours for the internal combustion at the center of the billet to fully burn, playing a role in fully utilizing all thermal energy.