軽量レンガ

Performance of aerated bricks

1. Lightweight: As a building material, it can reduce the weight of the building and significantly reduce the overall cost of the building.

2. Fire prevention: 主原料は無機物がほとんど, 耐火性に優れ、火にさらされても有害なガスを発生しません。.

3. 遮音性: 独特の多孔質構造により、, 一定の吸音能力があります.

4. 絶縁: 素材内部には多数の細孔や微細孔が存在するため、, 優れた断熱性能を持っています.

5. 不浸透性: 独立した多数の小さな孔で構成された素材のため, 水を吸収し、湿気をゆっくりと伝導します。. 同じ体積の水が飽和に達するまでに要する時間は、 5 粘土レンガの数倍.

6. 耐震性: 同じ建物構造の場合, それはです 2 粘土レンガを上回る耐震性.

7. 環境を守ること: 製造業, 交通機関, 使用プロセスは無公害です, 農地を守ることができる, エネルギーを節約する, そして消費を減らす. グリーンで環境に優しい建材です.

8. 耐久性: 材料強度が安定している.

9. 素早い: 加工性が良い, それは鋸で見ることができます, 計画した, 掘削された, そして釘付けになりました, and can be bonded with appropriate bonding materials, creating favorable conditions for construction.

10. Economy: Green, environmentally friendly, and energy-saving.

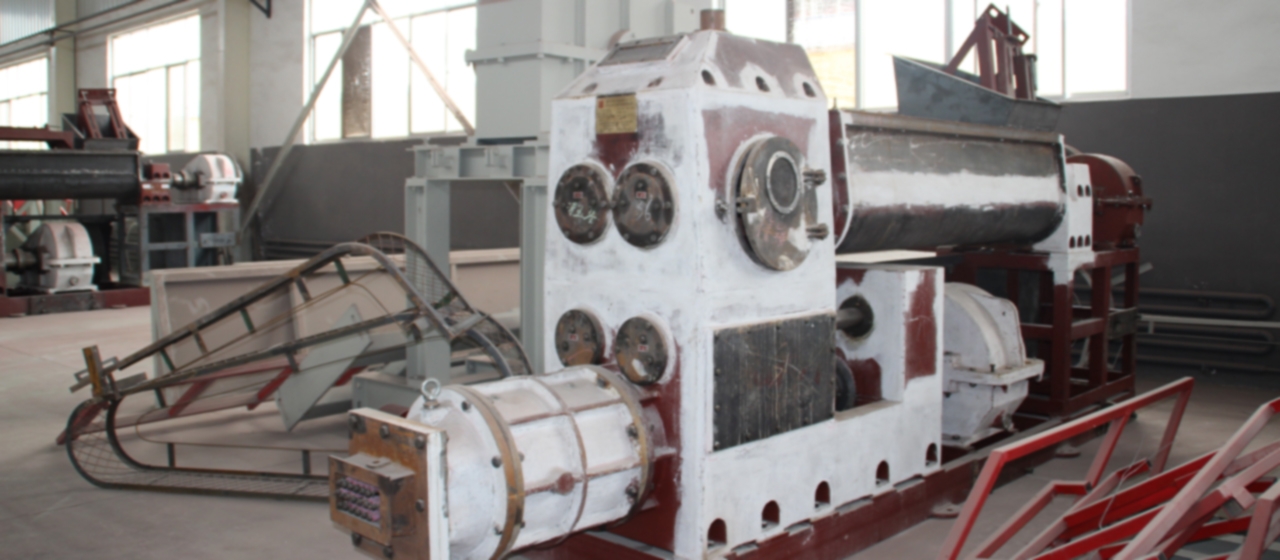

Aerated lightweight brick is a type of block produced using high-temperature steam pressing equipment technology. Its advantage lies in the ability to form closed holes inside the concrete, which makes it relatively lightweight and insulated. 実際には, concrete bricks are a special variety of aerated bricks, and their material properties and pore structure are relatively similar to those of aerated bricks. しかし, there are also some differences between the two. As for which one is more suitable for everyone to purchase, it is better to first read and analyze before making a decision.

From the perspective of subtle structural features

よく知られているように, foamed cement is a product that is connected by countless closed holes and has advantages such as sound insulation, heat insulation, and thermal insulation. Aerated concrete is a product that promotes the cement slurry to form a honeycomb shape from the gas, presenting a connected pore shape. つまり, from the perspective of detailed structure, concrete bricks do not have as good sound insulation, moisture prevention and other effects as aerated lightweight bricks.

From the perspective of implementation density

According to the survey conducted by Huayu editor, the current density of commonly used concrete bricks is generally below 500kg/m3, while the density of aerated lightweight bricks can be lower than this.

From the perspective of foaming methods

It should be noted that traditional concrete bricks are foamed using chemical methods, while aerated lightweight bricks use more flexible methods to complete this work. Specifically, by using a high-pressure air pump to inflate, as long as the closed pores formed by the concrete are reached, it is considered qualified, indicating that its foaming method is slightly more advanced.

From the perspective of maintenance technology

Because there are many types of aerated lightweight bricks, the corresponding oxidation processes are also quite diverse. 例えば, steam curing can be adopted according to different cementitious materials. The curing process of concrete bricks is relatively simple.