briques de briques creux

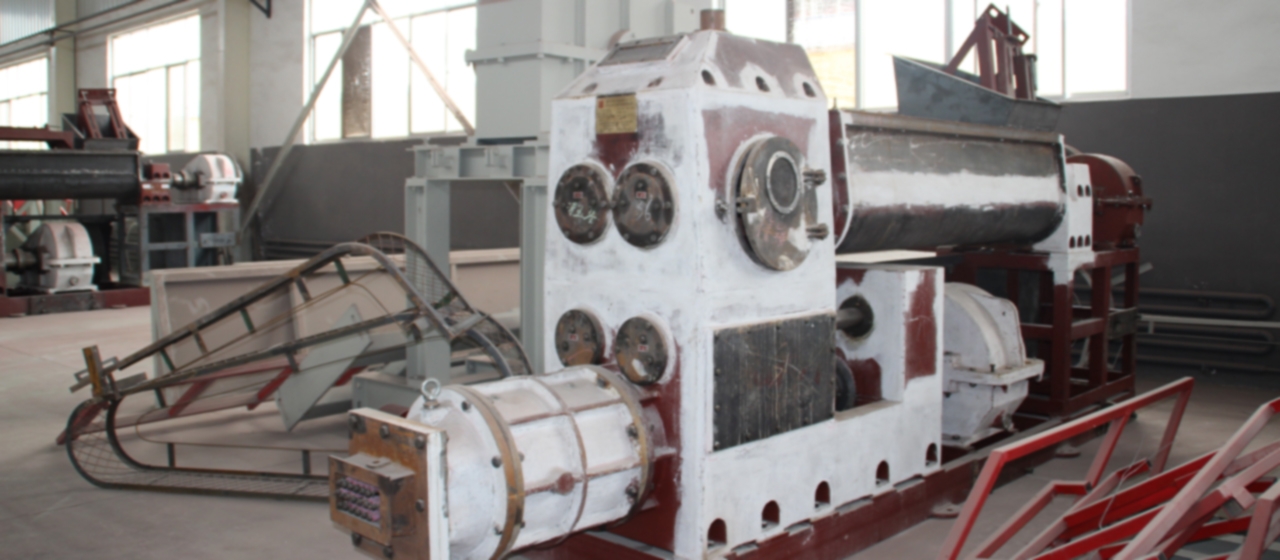

La machine à briques d'argile convient à la production de diverses spécifications des briques creuses et des briques standard de l'argile, schiste argileux, et les matières premières de gangue de charbon. La machine adopte une structure supérieure et inférieure, et peut être installé de manière droite ou en forme de T selon le terrain. Both the upper and lower level transmissions use type national standard reducers and axial pneumatic clutches, and the body is entirely welded from steel plates. The surface of the cutter adopts wear-resistant material spray welding technology, which extends the service life, is sturdy and durable, and easy to operate.

La fabrication de briques dans une usine de briques est très similaire à la cuisson à la vapeur de Mantou. Casser des matières premières équivaut à moudre du blé en farine. Mélanger des matières premières avec de l'eau, c'est mélanger de la farine; Entering the aging warehouse, the clay material undergoes aging, which is equivalent to fermenting the well made noodles in a basin; Le moulage consiste à transformer la boue en la forme souhaitée, qui est identique au Mantou réalisé en pétrissant la pâte fermentée, sauf que le Mantou est cuit à la vapeur, pendant que la brique est cuite à haute température.

Common molding process: multi bucket machine feeding → → belt conveyor → box feeder → → secondary mixing → brick machine (remixer) → cutting machine → billet cutting machine → grouping machine → billet coding machine → kiln car

Processus de formage spécial: multi bucket machine material taking → → belt conveyor → → box feeder → → wet wheel mill (ou concasseur à rouleaux) → → secondary mixing → brick machine (remixer) → → strip cutting machine → billet cutting machine → grouping machine → billet coding machine → kiln car

Pour faciliter la gestion, the aging warehouse is generally classified under the management of the molding workshop. La fonction du chargeur de caisse est d'alimenter uniformément et d'empêcher le flux de matériaux de fluctuer. Un flux de matériaux inégal n'affecte pas seulement le rendement de la machine à briques, but also affects the quality of the brick blank, because the upper mixing tank is adjacent to the extrusion section, qui est relié à la chambre d'extrusion de la machine à briques. In order to ensure the compactness of the brick blank, air is extracted from this chamber, which is called vacuum extraction. The denser the mud material in the extrusion section and the cylinder body, the better the vacuum effect and the higher the vacuum degree. À ce point, the compactness of the brick body will be better. But if the material flow is small, the sealing between the mud material in the upper mixing and extrusion section and the cylinder body will be poor, the vacuum degree will be low, and the compactness of the brick body will also be poor.

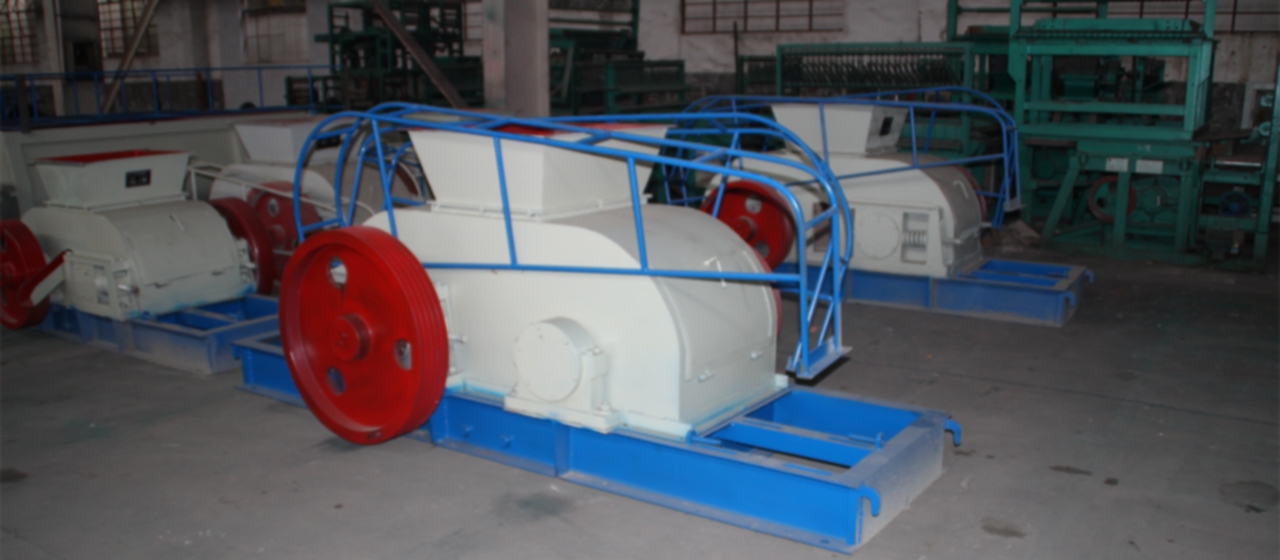

The function of secondary mixing is to adjust the moisture content of the mud material as an intermediate stage for further mixing, by adding water to make the mud material reach or approach the formed moisture content. There are two types of two stirrers. The traditional two stirrer is a double shaft mixer, which only plays a stirring role and is suitable for extruding soft and semi hard plastics; Single axis mixers are equipped with an extrusion section, which is designed to strengthen kneading and ensure even moisture distribution in the mud material, making it suitable for hard plastic extrusion molding.