Proyecto llave en mano para línea de producción de ladrillos de arcilla.

We supply full set of turnkey project for production line auto big capacity clay brick making machine , including the complete line design, engineering management, civil engineering of kiln and drying chamber, the foundation building, supplying, installation of all the equipments, the supplying and installation of compressed air, water and power system and etc. After we complete the whole project, we will pass the production lien to customer for using directly.

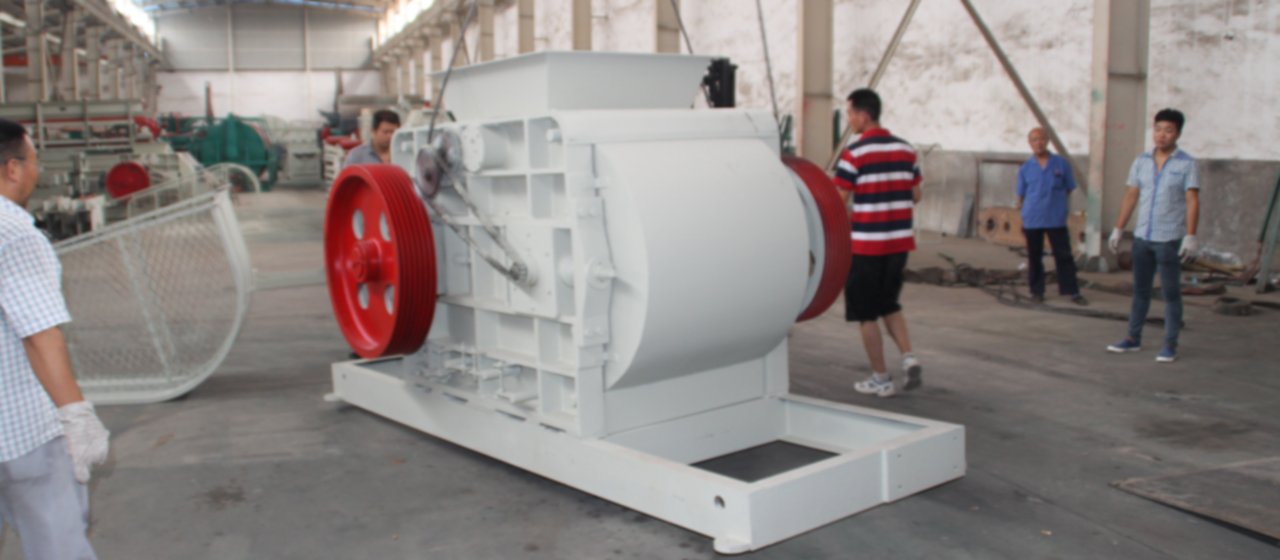

The main equipments on big capacity clay brick making machine producing line we can supply as bellow:

1. Raw Material Treatment Machine——–Box Feeder, Double Shaft Mixer, Trituradora, Convey.

2. Brick Forming Machine—-Double Stage Vacuum Extruder, Automatic Cutting Machine, Mixer and Extruding Machine.

3. Drying System——–Small Suction Tunnel Drying Chamber, Single Layer Dryer.

4. Firing System———Hoffman Kiln, Horno Túnel.

5. Automatic Brick Loading and Unloading Machine, Robot Brick Loading Machine.

Full automatic clay fire brick making machinery and brick making equipment

| Modelo | JKB55/50-35 clay brick molding machine |

| Capacidad de producción (piezas/hora) | 15, 000~18, 000 pieces (ladrillo estándar) |

| Presión de extrusión (MPa) | ≥ 3.5 |

| Presión de vacío | ≥ 0.092 |

| Conformación del contenido de humedad (base húmeda %) | 16 ~ 20 |

| Índice de plasticidad de la materia prima | 7 ~ 15 |

| Correa trapezoidal requerida | 8V |

| Bomba de vacío requerida (tipo de circulacion de agua) | 2SK ~ 12 |

| Energía (kilovatios) | 200+75 |

| Dimensión total mm largo × ancho × alto | 5500×5000× 2500 |