ladrillos de ladrillos huecos

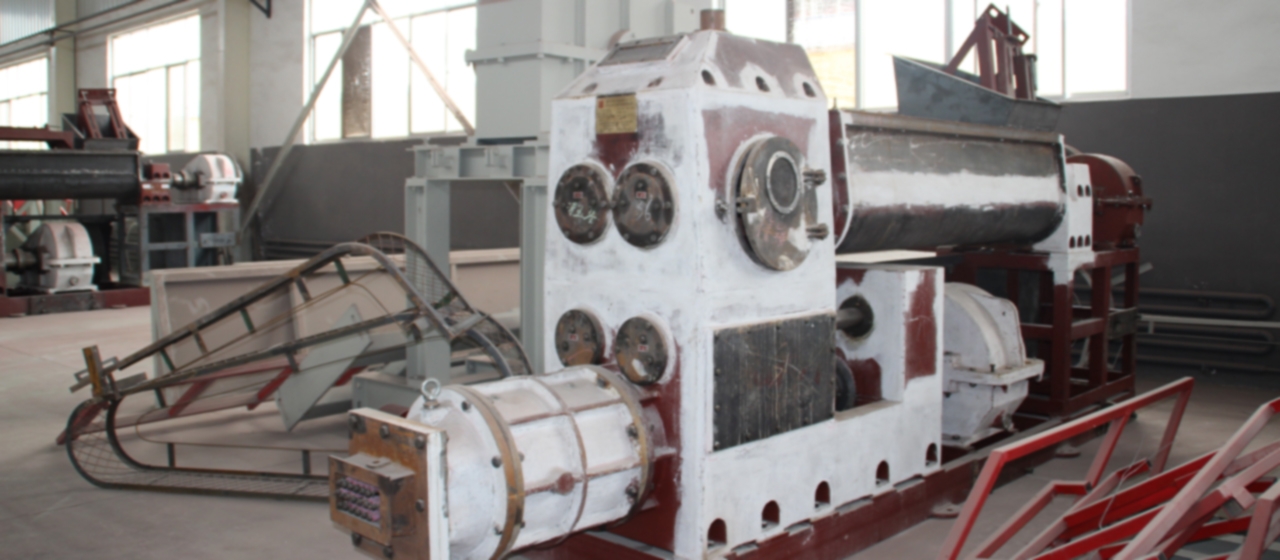

La máquina de ladrillo de arcilla es adecuada para producir varias especificaciones de ladrillos huecos y ladrillos estándar de arcilla, esquisto, y materias primas de carbón ganan. La máquina adopta una estructura superior e inferior, y se puede instalar de forma recta o en forma de T de acuerdo con el terreno. Both the upper and lower level transmissions use type national standard reducers and axial pneumatic clutches, and the body is entirely welded from steel plates. The surface of the cutter adopts wear-resistant material spray welding technology, which extends the service life, is sturdy and durable, and easy to operate.

La fabricación de ladrillos en una fábrica de ladrillos es muy similar a cocinar Mantou al vapor.. Romper las materias primas equivale a moler el trigo hasta convertirlo en harina.. Mezclar materias primas con agua es mezclar harina.; Entering the aging warehouse, the clay material undergoes aging, which is equivalent to fermenting the well made noodles in a basin; El moldeado consiste en procesar el barro hasta darle la forma deseada., que es idéntico al Mantou elaborado amasando la masa fermentada, excepto que el Mantou se cuece al vapor, mientras el ladrillo se cuece a alta temperatura.

Common molding process: multi bucket machine feeding → → belt conveyor → box feeder → → secondary mixing → brick machine (re mezclando) → cutting machine → billet cutting machine → grouping machine → billet coding machine → kiln car

Proceso de conformado especial: multi bucket machine material taking → → belt conveyor → → box feeder → → wet wheel mill (o trituradora de rodillos) → → secondary mixing → brick machine (re mezclando) → → strip cutting machine → billet cutting machine → grouping machine → billet coding machine → kiln car

Para facilitar la gestión, the aging warehouse is generally classified under the management of the molding workshop. La función del alimentador de cajas es alimentar uniformemente y evitar que el flujo de material fluctúe.. El flujo desigual de material no solo afecta el rendimiento de la máquina de ladrillos, but also affects the quality of the brick blank, because the upper mixing tank is adjacent to the extrusion section, que está conectado a la cámara de extrusión de la máquina de ladrillos. In order to ensure the compactness of the brick blank, El aire se extrae de esta cámara., which is called vacuum extraction. The denser the mud material in the extrusion section and the cylinder body, the better the vacuum effect and the higher the vacuum degree. En este punto, the compactness of the brick body will be better. Pero si el flujo de material es pequeño, the sealing between the mud material in the upper mixing and extrusion section and the cylinder body will be poor, the vacuum degree will be low, and the compactness of the brick body will also be poor.

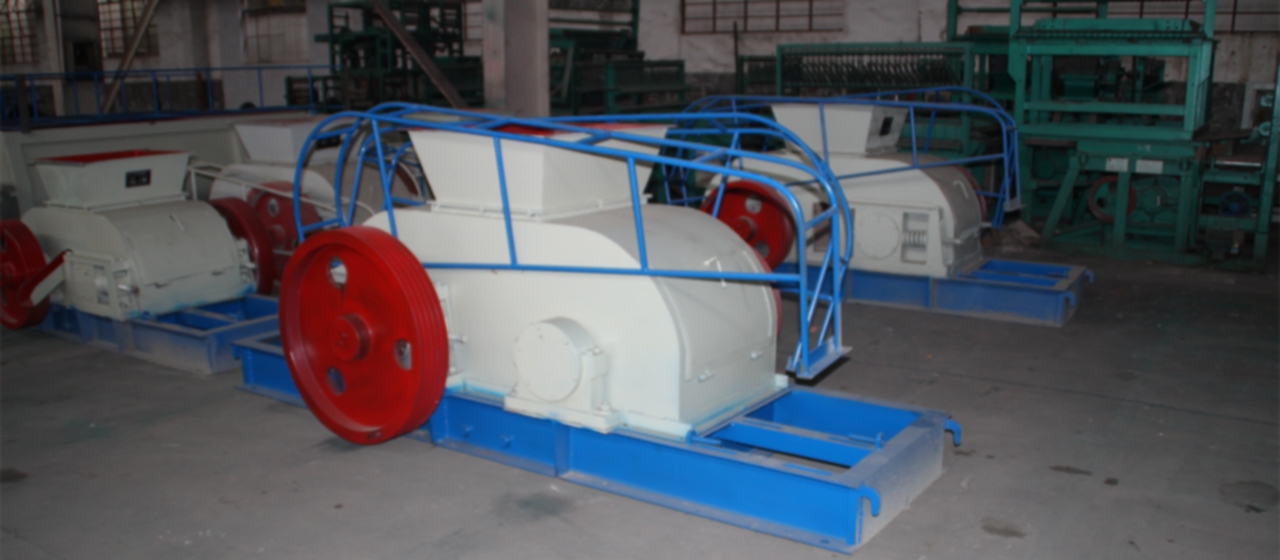

The function of secondary mixing is to adjust the moisture content of the mud material as an intermediate stage for further mixing, by adding water to make the mud material reach or approach the formed moisture content. There are two types of two stirrers. The traditional two stirrer is a double shaft mixer, which only plays a stirring role and is suitable for extruding soft and semi hard plastics; Single axis mixers are equipped with an extrusion section, which is designed to strengthen kneading and ensure even moisture distribution in the mud material, making it suitable for hard plastic extrusion molding.